Sanjay Soni is the Director of Si2 Microsystems. A Commerce Graduate from The Sydenham College, Mumbai and an MBA from the Indian Institute of Management, Bangalore (IIMB), he focuses on defence production and new ventures. Mr Soni has written several books on Computer Science and is a recipient of an award from former Prime Minister Rajiv Gandhi for his work on the increase of computer education in India in the early 90s.

In an interview with Raksha Anirveda, Mr Soni speaks his heart out on his company’s manufacturing capabilities and the customer base in India and abroad. An excerpts:

You are into the area of providing products and solutions to variety of defence, military, space and aerospace clients. Could you please elaborate on this?

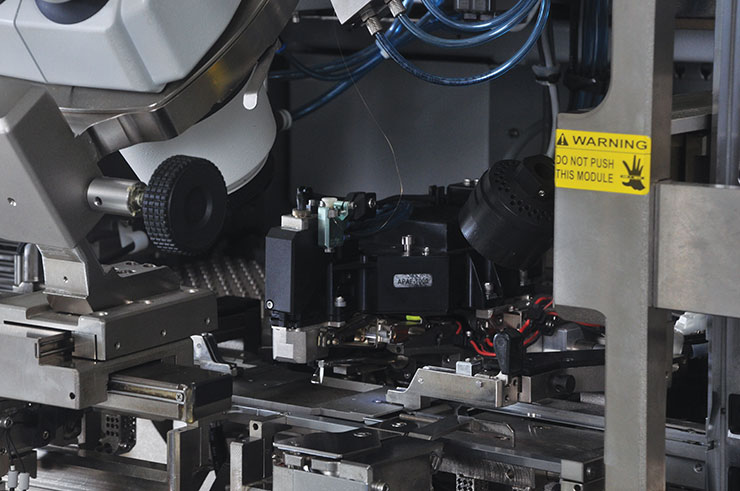

Sanjay Soni. Si2 Microsystems, established in 1996 is a leading manufacturer of micro-electronic, System-in-package (SIP), electronic systems and sub-systems to Indian and international customers – both commercial and defence. Si2 has manufacturing facilities in India and the United States. Customers include BEL, ISRO, ADE, HAL (India), MBDA Missile Systems, France, Elisra EW Systems, Israel etc.

Si2 is currently working on various military projects such as:

- Production of critical components for the Light Combat Aircraft – BEL

- Repair and overhauling of electronics of the MiG-27, MiG-29 and Su-30 – HAL

- Design and manufacture of Missile Testers – MBDA Missile Systems, France

- Manufacture of spares for T-72 and T-90 under indigenisation programme for Indian MoD in collaboration with M/s Uralvagonzavod, Russian Federation

- Design and production of various micro-electronics for ISRO

Si2 is also certified for manufacturing as per the AS 9100C Aerospace Quality Standard. Our design and manufacturing capability especially in the area of System-in-package is unique in India and has executed SIP projects for international clients as well.

Now with the opening of various Government agencies as facilitator and private industry associations as policy influencers, how do you see these developments towards defence and aerospace industry in India?

Sanjay Soni. These are very positive developments for the defence and aerospace industry in India and will help in creating an ecosystem for defence manufacturing in the private sector which doesn’t really exist today.

What’s your take on Ease of Doing Business (EODB) policy of the Government of India? Is it actually workable on ground? How far you benefited from it?

Sanjay Soni. The EODB policy is a good step forward. However, it still has to translate into real action at the ground level. We are not seeing any benefits so far as it is still at an early stage and it would take time for the policy to percolate down and translate into real progress at the level that industry interacts with various government agencies whether central or state.

Your company Si2 Microsystems is into the area of manufacturing high quality products and reliable solutions. Are the solutions indigenous? If not, what percentage of products, solutions or technology you import?

Si2 Microsystems is into the area of design and manufacturing of innovative high-tech products and reliable solutions. The solutions are indigenous because the people designing the solutions are Indian! We use a small percentage of imported components, say around 35-40 per cent but that is unavoidable as those are not available in India.

How far do you feel the Government policy has been eased to promote Make in India?

Sanjay Soni. The Make in India policy has been very helpful in creating a demand for indigenous solutions. There is no doubt about that. However, until a level playing field is created wherein Indian companies are treated in the same manner as the DPSUs or foreign suppliers, the Make in India programme will not achieve its full objective and true potential. Indian companies are still discriminated against by the Armed Forces and DPSUs by their insistence on putting onerous conditions and financial obligations on them, which are not levied on foreign companies. Secondly, the tax terrorism has to stop if Make in India has to succeed. This is most critical as nearly all manufacturing companies in India are spending a lot of time and resources fighting against the indirect and direct tax departments.

Did you collaborate with foreign companies/ any other OEMs for Technology Transfer or any other assistance to Make in India. If so, for what kind of products or solutions?

Sanjay Soni. Yes we do. Without critical technology transfer from foreign OEMs it is not possible to manufacture some of the defence equipment in India. We are working with several Russian companies to manufacture spares for the tanks as well as combat aircraft. We are also working with Israeli companies for manufacture of very sophisticated components for Radars.

Name the latest technologies you are using in the manufacturing of the products and solutions? Are the technologies you are using absolutely indigenous?

Sanjay Soni. The technologies we are using such as SIP for 3D packaging is really cutting edge. However, this technology has evolved over the years in US & Europe. What is indigenous is the implementation of this technology. It can be implemented in many innovative ways and some of the implementations done at Si2 are very unique, especially in the creation of innovative solutions in 3D packaging for usage in the Aerospace and Space industry.

As seen you have a separate vertical of Make in India. What type of strategic solutions you are into for Indian Defence Programmes and how it’s contributing to Make in India?

Sanjay Soni. We are working on providing anti-jamming equipment for combat aircraft, digital upgradation of air defence missile systems, upgradation of electronics for the T-72 and T-90 tanks etc. These are all being undertaken under the Make in India programme. We have not only been able to indigenise several sub-systems but have also lowered the cost of the same for the user!

In the light of recent security threat and the Government’s special thrust to secure the country internally too, do you have any solutions on provision. If yes, please explain?

Sanjay Soni. Yes, we do have solutions to improve internal security of the country. We have provided several solutions in the area of Perimeter Intrusion Detection Systems, Sophisticated Airborne Surveillance Equipment, Critical Asset Tracking Solutions etc. These are under evaluation by various government agencies.

Indian Space Programme seems to becoming self-reliant. What’s your take on that, and your organisation is contributing to this?

Sanjay Soni. ISRO is one of the earliest organisations in India which moved towards becoming self-reliant. They have achieved a lot in this endeavour. We have been working with ISRO since 2010 and have executed several projects especially in SIP and miniaturisation which have helped it to reduce the weight of the satellites and increase the payload.

Your achievements so far?

Sanjay Soni. Si2 has numerous achievements to its credit. Some of them are:

- Production of missile launcher testers for an international client

- Pioneer in design and co-development of anti-jamming equipment

- Has produced several SIP and 3D packages for even highly demanding Israeli customers among others

- Have created a whole suite of IOT products for the Smart City project using its own RF Modules of ZigBee and LoRa technology

Do you see a boost to Make in India/ Indigenisation in the backdrop of recent decisions taken by Cabinet Committee on Security (CCS) headed by Defence Minister Nirmala Sitharaman?

Definitely. The recent decisions taken by the CCS are a step in the right direction and will boost the Make in India programme in a big way. There is no doubt about that.

Your final comment, if any?

Sanjay Soni. Technical qualification of Indian vendors is essential in the defence and aerospace arena. L1 cannot be the sole criteria for selection of a company to take up critical projects of indigenisation. The buyer has to create a pool of qualified vendors and only they should be eligible to bid for tenders which involve high precision and require complex engineering skills and infrastructure.