Backdrop

A nano particle invisible to the naked eye has changed the world i.e. COVID 19 virus. The world order, the lifestyle, the social and emotional connects…..everything is trying to adjust to the new normal. The new world order has largely affected the geo-political scenario, international alliances and also the business strategies. This has prompted India to establish itself firmly on the world canvas and initiate steps to be more self reliant in every sector including the defence and security sector. India has been recognised as the seventh largest military spending nation, but in 2016, it has moved up to the fourth largest military spending nation in the world.

India’s defence and security budget has been increased from Rs 14,7,344 crores in 2010-11 to Rs 47,1,378 crores in 2020-21 with a total increase of 219.9 per cent in 10 years at an average of 21.9 per cent annually. India has been pushing for greater indigenisation of military hardware as India imports around 70 per cent (by value) of its high-tech defence hardware such as aircraft, ships, submarines, missiles etc. mainly from Russia, Japan, Israel and United States.

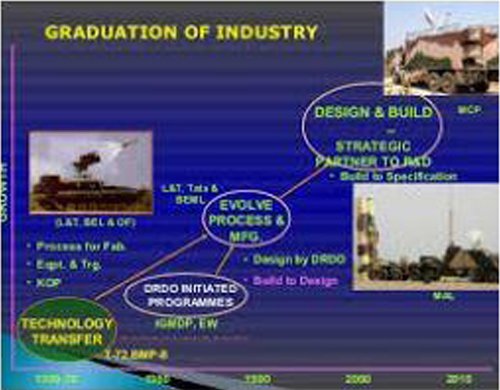

Our country inherited a couple of Ordnance Factories (OFs) from the British era and established DRDO in 1950. However, there has been significant growth in the later part of the 20th century along with rapid progress in the last 20 years. In the 1980s, India began a renewed effort to galvanise its domestic defence industry by development of indigenous missile systems such as ‘Prithvi’, ‘Akash’ and ‘Nag’. India also began the development of the Light Combat Aircraft (LCA) during this period. In 1998, India entered into an agreement with the Russia to develop a supersonic cruise missile system, ‘BrahMos’, through a joint venture.

Does India Possess the Knowledge and Manufacturing Base to Become Self Reliant?

Besides the fact that from 2000 to 2020, India’s defence budget allocation increased from Rs 58,587 crores to Rs 471,378 crores, India has recently allowed the private sector to enter the defence production. India’s defence exports were Rs 4,682 crore (US$0.66 billion) in 2017–2018 and Rs 10,500 crore (US$1.47 billion) in 2018–2019, and are expected to increase exponentially in next few years due to aggressive measures taken up by the government since 2014. A look at the following would prove amply that Indian manufacturers have been slowly and steadily developing the skills, expertise and the manufacturing base in defence sector:

• Since 2015, major Aerospace & Defence companies such as, Airbus with Mahindra Defence Systems, Boeing with Tata Advanced Systems, Lockheed Martin with Safran already have a footprint in the Indian market, to manufacture military helicopters, fuselage of Apache helicopters etc.

• Launch of fast tracked projects like undocking of six Scorpene diesel electric attack submarines, induction of the indigenously produced LCA Tejas, besides the missile systems are testimony of India’s footprints in the sector. In addition, India has signed defence cooperation agreements and MoUs with over 20 countries including the United States (as a ‘major defence partner’), enabling license-free access to a wide range of dual-use technologies.

• India is also in the process of jointly developing a fifth-generation stealth combat aircraft with Russia under the PAK-FA programme.

• Sale of first indigenously designed and built multi-role offshore patrol vessel (OPV) named Barracuda, to Mauritius and sale of indigenously developed lightweight torpedoes worth US$37.9 million to Myanmar.

• Ordnance Factory Board (OFB) secured its biggest export order from UAE for the supply of 40,000 numbers of 155 mm artillery shells for Rs 322 crore and supply another 50,000 artillery shells.

• Indian forces are using numerous successful indigenous technologies produced by the Defence Research and Development Organisation (DRDO), including Varunastra, Maareech, Ushus, TAL by navy; Electronic Warfare Technologies, radars, composite materials for LCA, AEW&C, Astra, LCA Tejas by Air Force; and ASAT, BrahMos, ASTRA, Nag missile, SAAW, Arjun MBT Mk 1A, 46 metre Modular Bridge, MPR, LLTR Ashwin by the Army.

• FDI in defence sector increased from US$0.8 million in 2014-15 to US$2.18 million in 2018-19.

• The indigenously developed warships INS Kochi and INS Kolkata have been commissioned with the INS Kalvari Attack Submarine undergoing sea-trials.

• The indigenously developed Akash Surface to Air Missile Defence System has become fully operational.

Steps Taken by Government to Boost Indigenous Defence and Security Industry:

The present government has been very proactive to enhance defence production within the country. Defence Production Policy of 2018 (DPP-2018) has a goal of being among the top five global producers of the aerospace and defence manufacturing with annual export target of US$5 billion by 2025. Various steps taken by the government in this regard are:-

• Smart Cities and Surveillance Projects announced.

• More than 100 projects with Rs 10,000 cr+ announced in last five years related to security and surveillance in PAN India including the coastal surveillance.

• Facial recognition technology and other AI related technologies integrated with IoT have been encouraged by the government under Micro, Small and Medium Enterprises (MSMEs) to flourish, under the Make in India scheme. Same are following the export path now.

• Digital Forensic industry has started flourishing with minimum of Rs 70cr of business annually, encouraging MSMEs to participate and to make the investigations more efficient.

• Efforts to get FDI in defence sector by first raising the cap from 26 to 49 per cent through automatic route and 100 per cent through the approval from Ministry of Defence (MoD), whereby the investing foreign entity can have ownership up to 100 per cent in the defence manufacturing.

• Introduction of various categories of defence projects such as Buy Indian-IDDM (Indian Designed, Developed and Manufactured), Buy Indian, Buy Global, Buy & Make (Indian), Buy & Make is likely to boost the PSUs as well as private industry.

• Funding of private sector design and development projects with a special focus on the Medium and Small Manufacturing Enterprises (MSME) Sector.

• Streamlining of defence exports resulting in significant increase of the same.

• Defence cooperation agreements and memorandums with 20 countries.

• Strengthening of strategic partnerships with US, Russia and EU nations to facilitate transfer of technology.

• Government of India banned import of 101 defence items to boost indigenous production in consonance with Modi government’s Atmanirbhar Bharat.

Additional steps announced by the Prime Minister and Defence Minister during web conferencing on August 27:

• Government has set up defence and industry corridors in Uttar Pradesh and Tamil Nadu. Companies as well as organisations will get preference in registration, manufacturing and ease of business.

• Firing ranges will be made available to the manufacturers for testing and demonstration. A better system for Proof of Concept (POC) will be implemented to improve smooth demonstration.

• Relaxation in export licensing policies.

• Import restrictions to be extended to more equipment in order to promote indigenous products.

• Corporatisation of Ordnance Factory Board (OFB) to bring competitiveness, remove bureaucratic procedures.

• Project Management Units will be set up to monitor project delivery with Quality Control and adherence to Internationally-accepted standards.

What Needs to Be Done to Achieve Results

While the government has taken significant and encouraging steps to promote defence manufacturing and exports, the bureaucracy and industries need to gear up to meet the challenge. In order to compete with Tier 1 manufacturers, it is recommended that the following steps be taken at various levels:

❖ Raw Material Strategic partnerships and MoUs need to be signed with various countries for procurement of raw material.

❖ Bureaucracy In the past, companies have been known to shy away from setting up manufacturing plants in India due to complex and cumbersome procedures and inordinate delays. The bureaucracy should design, plan and implement single window, online, user friendly procedures for grant of licenses for setting up plants, exports, imports, attracting FDI. In addition, corruption free environment will be a major attraction and added environment.

❖ Industries and Directorate General of Quality Assurance (DGQA) The products need to meet various quality standards in order to be able to compete foreign manufacturers. In this regard, while the industries need to undertake R&D as well as upgrade the technology base and skills of workers, the DGQA is expected to whole heartedly support them as regards testing and certification of the products, assemblies, sub assemblies and components. In view of this, the following issues will be significant:

✓Designing of policies and procedures for quality assurance and testing. These will have to be customised for each product including COTS/ MOTS items.

✓Laying down and implementing strict time plan. For this purpose, additional testing facilities and staff may be required in the country.

✓The Directorate of Standardisation needs to speed up the process of correlating and allocating cat part numbers to avoid unnecessary delays.

❖ Steps to reduce brain drain from the country and promote R&D, think tanks for defence sector. This needs to be a deliberate attempt at the level of industries, government, prestigious institutes as well as organisations.

❖ R&D It is recommended that DRDO and private industry need to cooperate in this field and share the knowhow and access to procured/ developed technologies. In this regard, the funding is recommended on Public Private Partnership (PPP) basis to share the financial burden.

❖ Infrastructure It is recommended that the infrastructure of Ordnance Factories should be made available to private industries. Partnership between large firms and MSMEs need to be promoted for developing a larger industrial base, skilled work force and faster production. MSMEs can be used for producing small components, sub assemblies and parts including maintenance tools.

– The author is an Indian Army veteran, and has been Principal Consultant to Department of Urban Development, Govt of MP for Smart City Projects. He can be reached at: manoj_42ch@yahoo.co.in and the co-author is a seasoned management professional, and has been associated with various think tanks in defence and security. Views expressed are personal and do not necessarily reflect the views of Raksha Anirveda